Just for our consumers’ peace of mind, we offer 12 months or 12,000 miles / 20,000 km limited warranty on MÜLLER brake pads.

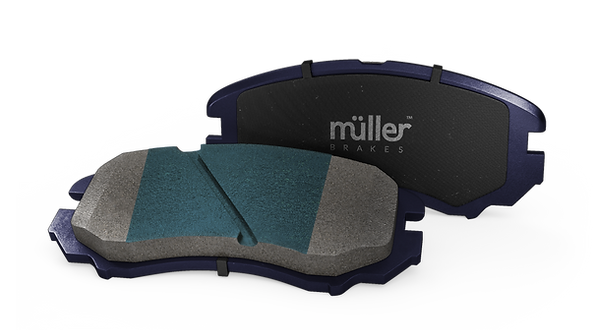

PREMIUM METALLIC

BRAKE PADS FEATURES

-

40,000 to 50,000 km lifetime

-

100% asbestos-free formula

-

Superior heat transfer and resistance in all driving conditions

-

Exceptionally long brake pad and rotor life

-

Outstanding braking performance for small cars & sedans

-

Economical and reliable

-

No break-in needed

-

Substantial reduction in dust

Positive Molding Technology is an essential factor in the production of MÜLLER products. Positive molding results in a more uniform density in the brake pad production. It also allows using less resin content in the formulation of the brake pad, which can improve the fading characteristic of the brake pad. The brake pads produced by the positive molding process have much better-stopping performance. High resin increases fading, increasing stopping distances up to 50%.

All MÜLLER brake pads are manufactured using the same positive molding process utilized by Original Equipment suppliers. Positive molding uses extreme pressure to compress and bond the friction material to the backing plate. This process assures consistent friction material density throughout the pad, resulting in even wear and performance characteristics throughout the brake pad's life.

POSITIVE MOLDING

TECHNOLOGY

MAIN FEATURES

-

Maintains constant friction consistency

-

Ensures better braking performance

-

Delivers longer service life

-

Requires less resin material

-

Resists heat fade

* MÜLLER Brake Pads are AMECA certified. Formula is tested by an accredited laboratory and registered by NSF for AASA LeafMark. (Most formulas are in compliance with the copper requirements for the States of California and Washington) Most part numbers are certified for E-Mark ECE-R90 by VCA.

PREMIUM FRICTION

MATERIAL & OE STC

In order for a newly installed brake pad to have superior braking performance and comfort from the start, MÜLLER uses OE STC coating that delivers a shorter bedding-in period and an efficient brake operation, right from the first brake use.

OE STYLE

BACKING PLATE

Available in Wire-drawing and Hole Drilled types.

ANTI-RATTLE 3 LAYER OE

MATCHING SHIMS

We use the most advanced

Anti-Rattle Shims technology

to ensure a quiet breaking performance for drivers.

In addition to these features, MÜLLER has added a Coating Layer to all its brake pads. MÜLLER has added the OE STC on its brake pads to enhance their performance and longevity. The OE STC typically consists of a ceramic-based material that is applied to the brake pad surface during manufacturing.

This coating process enhances key friction performance levels. The OE STC reduces noise and works on both brake pads

and disc rotor performance.

The purpose of the OE STC is to improve several aspects of brake pad performance:

Reduced Noise: OE STC can help dampen vibrations and reduce noise generated during braking, resulting in quieter operation.

Improved Wear Resistance: The material in the coating can provide increased resistance to wear and abrasion, leading to longer brake pad life.

Enhanced Heat Dissipation: The coating can help dissipate heat more efficiently, reducing the risk of brake fade under heavy braking conditions.

Better Performance: OE STC can contribute to improve braking performance by providing consistent friction characteristics and reducing brake fade.

OE STC works on both brake pads and disc rotors performance especially if the surface of disc rotors has some

irregularities or improper surfaces.

MÜLLER PREMIUM

METALLIC BRAKE PADS

In today’s high horsepower vehicle, nothing is more important than the brake system. Suppose you have noticed strange noises or squeaking when braking, unusual shaking when you apply the brakes, or uneven pulling to one side; these might be indications of worn brakes needing replacement. MÜLLER is a leader in brake technology and has the experience to deliver premium metallic brake pads that promotes better heat transfer, providing quality braking every time.

EXCEPTIONAL BRAKING TECHNOLOGY

MÜLLER Premium Metallic Brakes Pads are made from an organic formula combined with small amounts of metal that help with heat transfer to offer improved braking. They are designed to keep wheels exceptionally clean and deliver first-rate stopping power in a shorter stopping range. Exceedingly rotor friendly, these brake pads are ultra-quiet with no break-in required. Delivering the ultimate performance and the safest braking experience, our high-performance metallic brake pads are 100% asbestos free and made with first-rate brake friction material, providing optimal heat resistance for all kinds of driving conditions and weather.

* Based on best of our knowledge and In comparison with each others.

Quiet Performance

Smooth

Braking

Stopping

Power

Dust Free

Lifespan

Professional Carbon Metallic

Recommended for All Passenger

Cars & SUV(s)

SUPERB

.png)

SUPERB

SUPERB

EXCELLENT

EXCELLENT

Professional Carbon Ceramic

Recommended for All Passenger Cars

& SUV(s) including high-end

SUPERB

SUPERB

SUPERB

SUPERB

SUPERB

Premium Metallic

Recommended for All

Passenger Cars

GOOD

.png)

EXCELLENT

EXCELLENT

GOOD

GOOD

Premium Organic

Recommended for All

Passenger Cars

GOOD

EXCELLENT

EXCELLENT

EXCELLENT

GOOD

Severe Duty

Recommended for All

Fleet Vehicles

GOOD

EXCELLENT

SUPERB

GOOD

SUPERB

* Based on best of our knowledge and In comparison with each others.

CERTIFICATIONS

E-mark ECE R90 by VCA

MÜLLER has obtained E-Mark ECE R90 certification, which is required for all brake products to be used throughout the European Union and other countries that have adopted to ECE regulations.

AMECA

MÜLLER has been granted the AMECA certification, which is in compliance with applicable United States standards.

AASA LEAFMARK

LeafMark is a trademark which is created by AASA and sublicensed by NSF. MÜLLER brake pads have been approved by an NSF accredited laboratory and awarded the LeafMark certification.

.png)